Introduction

Milk is a staple in diets around the world, valued for its rich nutritional profile and versatility. However, in its natural state, milk undergoes a process known as cream separation, where the fat globules rise to the top, forming a layer of cream. To prevent this and ensure a uniform consistency, milk undergoes homogenization. This article delves into the homogenization of milk, exploring its history, process, benefits, and impact on health and nutrition.

1. What is Homogenization?

Homogenization is a mechanical process that breaks down fat globules in milk into smaller sizes ( less than 2 microns ), preventing them from separating and forming a cream layer.

This ensures that the milk remains uniform in texture and appearance, with the fat evenly distributed throughout the liquid. The result is milk that has a consistent taste and longer shelf-life.

2. History of Milk Homogenization

Previously, or more accurately, prior to the introduction of homogenization, the process of milk processing was not particularly elaborate. Another traditional method of processing dairy products involved farmers skimming the cream from the milk by pouring it since the fat and water did not combine. Saturated approach: This method was time-consuming and so required a large amount of manpower, and the quality of the milk produced was not uniform.

The major leap in milk processing was achieved in the late 19th century with the discovery of the homogenizer. The first homogenizer was invented and patented in France in the year 1899 by Auguste Gaulin; the machine was invented to reduce the size of fat globules in milk to avoid coagulation. The enhancement made by Gaulin was in injecting the milk through small tubes at rather high pressure to distribute the fat content evenly.

This invention of Gaulin can be said to be the genesis of current milk homogenization procedures. He brought this to the Paris World Exposition in the year 1900, his creation caught the eyes of the people. He patented techniques that provided a basis for future advancements in homogenization processes increasing the efficiency of milk processing by venturing uniformity.

The history shows that homogenization in the dairy industry started to appear in the early period of the twentieth century. First, the issue might have been faced like ensuring homogenized milk has the right texture and is safe for drinking. However, as technology advanced the process also received a boost. Sometime during the 1930’s homogenization grew to be popular in so many dairies and this in one way or the other had a big impact on the production of milk.

Technological innovation in homogenization equipment emerged in the historical period after World War II and the process was further standardized. The development of homogenizers operating at high pressure and enhancements on the aspects of sanitary design made homogenized milk safe, standardized, and of premium quality. These developments made it possible to produce and distribute large quantities of milk and stabilize its consumption due to the qualities of the final product.

The process made a huge transformation to the dairy and it improved the shelf-life of milk and the quality too. In the present time, it is one of the most vital aspects because consumers are provided with quality milk having homogenized characteristics.

3. Why is Milk Homogenized?

Milk is homogenized primarily to prevent the natural separation of cream from the liquid. In unprocessed milk, fat globules rise to the top, creating a layer of cream. Homogenization breaks these fat globules into much smaller sizes, ensuring they remain evenly distributed throughout the milk. This process results in a consistent texture and appearance, making the milk more appealing to consumers.

1. Taste and Texture

There are several benefits to homogenizing milk. Firstly, it improves the taste and texture. Homogenized milk is smoother and creamier, without the graininess that can occur when cream separates. This uniformity enhances the sensory experience of drinking milk and using it in various culinary applications.

2. Extended Shelf Life

Another significant advantage is the extended shelf life. Homogenization stabilizes the milk, preventing the separation of fat and other components, which in turn helps maintain its freshness and quality over time. This is particularly important for large-scale distribution and storage, ensuring that milk remains consistent from production to consumption.

3. Easy to digest

Additionally, homogenization can make milk easier to digest for some people. By breaking down fat globules into smaller particles, the process can aid in more efficient digestion and absorption of milk fats. Some studies suggest that homogenized milk may be less likely to cause digestive discomfort, making it a preferable choice for individuals with sensitive digestive systems.

In summary, milk is homogenized to enhance its consistency, texture, and shelf-life, making it a more appealing and reliable product for consumers while potentially improving its digestibility. This process is a critical step in modern dairy production, ensuring that milk meets the high standards of quality and uniformity expected in today’s market.

4. The Process of Homogenization

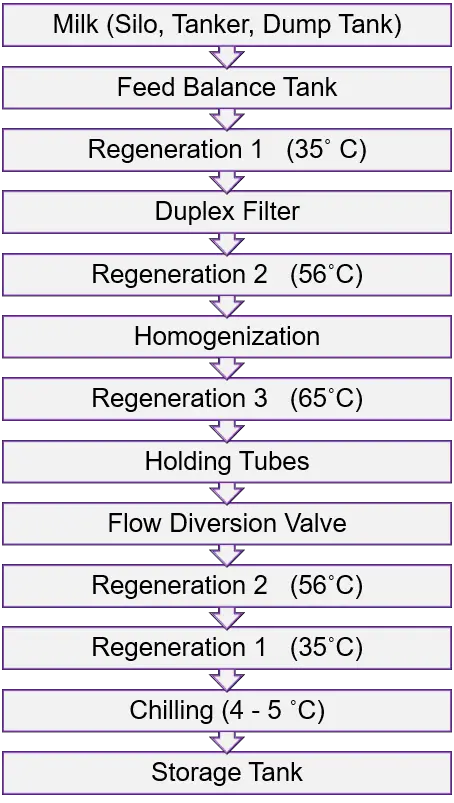

Homogenization involves several steps and specialized equipment:

- Pre-heating: Milk is heated to a specific temperature to reduce viscosity.

- Pressurization: The heated milk is forced through small orifices under high pressure, breaking down the fat globules.

- Cooling: The milk is quickly cooled to preserve its nutritional properties.

The 1st pressure that the milk experiences is 2000 psi ( per square inch ) & if the fat globules tend to clump again, then the milk experiences a 2nd pressure of 500 psi. During the setting of pressure in the homogenizer, firstly 500 psi & then 2000 psi pressure is set.

Milk homogenization temperature: 65 ˚ C

5. Effects of Homogenization on Milk

Physical Changes Due to Homogenization

1. Changes in Texture

That is why, modification of texture is considered to be one of the most profound consequences of the homogenization process. It emulsifies the fat particles making them of similar size and consequently, the product has a smooth and creamy texture. Such qualities are favored by many consumers, and they assist in ensuring that the quality of milk remains constant throughout its lifecycle within the supermarkets and other selling centers.

2. Impact on Colour

Homogenized milk looks much whiter and even more opaque than non-homogenized one and has a smoother, richer feel in the mouth. This change of color is due to the fat particles that are evenly suspended in the milk; hence they provide higher light scattering, and thus the milk appears the best.

3. Enhanced Stability

This process substantially improves the shelf life of milk since it does not allow the cream to rise to the top. This process adds to the shelf-life of milk since it enhances its homogeneity and prohibits the layering of the cream. Therefore, homogenized milk can be kept for a longer period before it starts spoiling because the qualities of the milk are not altered drastically.

Nutritional Impact of Homogenization

1. Effect on Vitamins

Food homogenization on its part does not cause any major shift in the vitamin content of milk. Some of the vitamins such as A and D are unaltered in the process. Nonetheless, these vitamins may also be impacted by the bioavailability, since the smaller fat globules increase fat soluble vitamins’ absorption.

2. Mineral Composition

The level of minerals in milk especially the major essential minerals such as calcium and phosphorus are not significantly altered by homogenization. These minerals are important for skeletal structure and other metabolic processes milk should retain these nutrients when put through a homogenization.

3. Protein Content & Structure

Though the total amount of protein that goes into making milk is constant, homogenization prolongs the structure of milk proteins. This may influence how easy it is for the proteins in milk to be broken down, which may prove beneficial to some persons. Moreover, such a change in protein should surely prove effective in altering the allergenicity of the milk as well.

6. Comparing Homogenized and Non-Homogenized Milk

Homogenized milk and non-homogenized milk offer distinct characteristics, influencing consumer preference and usage.

1. Texture and Appearance

Homogenized milk has a smooth, uniform texture and consistent appearance because the fat globules are broken down and evenly distributed. This prevents the cream from separating and rising to the top. Non-homogenized milk, on the other hand, will naturally separate, forming a cream layer at the top, which needs to be stirred back in before consumption.

2. Taste

The taste difference between the two is subtle but notable. Homogenized milk has a consistent flavor profile, which many find appealing for everyday use. Non-homogenized milk often retains a richer, creamier taste due to the presence of intact fat globules and the natural cream layer.

3. Nutritional Differences

Nutritionally, both types of milk are similar in terms of vitamins and minerals. However, the bioavailability of certain nutrients, particularly fat-soluble vitamins, may be higher in homogenized milk due to the smaller fat globules. Some people find non-homogenized milk easier to digest and believe it to be more natural and less processed.

4. Health Implications

There are ongoing debates regarding the health implications of homogenized versus non-homogenized milk. Some studies suggest that homogenized milk may be easier to digest due to the smaller fat particles. Conversely, others argue that the natural structure of non-homogenized milk might be better for those with specific dietary sensitivities.

5. Shelf-Life

Homogenized milk typically has a longer shelf life due to the stabilization of fat particles, which helps maintain quality over time. Non-homogenized milk, with its natural separation, might spoil faster if not handled properly.

In summary, the choice between homogenized and non-homogenized milk depends on personal preference for texture, taste, and beliefs about health benefits. Both types offer valuable nutritional benefits and serve different consumer needs.

7. Health Implications

The health effects of homogenization are a topic of ongoing research. Some studies suggest that homogenized milk is easier to digest, while others raise concerns about its allergenic potential.

Homogenized milk, while widely consumed and generally considered safe, does have certain health implications worth considering.

1. Digestibility

One of the key health benefits of homogenized milk is improved digestibility. The process breaks down fat globules into smaller, more uniform sizes, which can aid in more efficient digestion and absorption. This can be particularly beneficial for individuals with sensitive digestive systems or lactose intolerance.

2. Nutrient Absorption

The smaller fat globules in homogenized milk can enhance the bioavailability of fat-soluble vitamins like A, D, E, and K. This means that the body may more efficiently absorb these essential nutrients, potentially leading to better overall nutrition.

3. Allergenic Potential

There is some debate about the allergenic potential of homogenized milk. While homogenization itself doesn’t create allergens, the process can alter the structure of milk proteins. Some researchers suggest this might increase the milk’s allergenic potential, though conclusive evidence is lacking. People with milk allergies should consult healthcare providers regarding the suitability of homogenized milk.

4. Cardiovascular Health

Concerns have been raised about the impact of homogenized milk on cardiovascular health. Some early studies suggested a link between homogenized milk and an increased risk of heart disease, hypothesizing that smaller fat particles might pass more easily into the bloodstream. However, subsequent research has not conclusively supported these claims, and homogenized milk is generally considered safe in this regard.

5. Naturalness and Perception

Some consumers perceive non-homogenized milk as more natural and less processed, believing it might have health benefits associated with its traditional form. However, for most people, homogenized milk remains a nutritious, safe, and convenient choice.

In summary, while homogenized milk offers improved digestibility and nutrient absorption, individuals with specific health concerns should consider these factors and consult with healthcare professionals as needed.

8. Homogenization in the Dairy Industry

Homogenization is a standard practice in the dairy industry, ensuring consistency, quality in milk production, and appeal of milk products.

1. Process and Equipment

Homogenization involves breaking down fat globules in milk into smaller, uniformly distributed particles. This is achieved by forcing milk through small orifices at high pressure using specialized equipment called homogenizers. The result is milk that does not separate, maintaining a consistent texture and appearance.

2. Quality and Consistency

The primary benefit of homogenization is the production of milk with a uniform texture and stability. This prevents cream from rising to the top, which can be unappealing to consumers. Homogenized milk has a longer shelf-life, as the even distribution of fat helps maintain its quality over time. This consistency is crucial for large-scale dairy operations, ensuring that every batch of milk meets the same standards.

3. Nutritional Integrity

Homogenization does not significantly alter the nutritional content of milk. Essential vitamins and minerals remain intact, although the process can enhance the bioavailability of fat-soluble vitamins. The improved digestibility of homogenized milk is an additional benefit, making it a preferred choice for many consumers.

4. Industrial Efficiency

Homogenization increases production efficiency, allowing dairy producers to process large volumes of milk quickly and effectively. The process is integral to the standardization of milk products, facilitating widespread distribution and marketing. It also aligns with quality assurance protocols, ensuring that milk is safe and free from contamination.

5. Consumer Demand

The demand for homogenized milk is driven by consumer preferences for a smooth, consistent product that stays fresh longer. This process supports the dairy industry’s goal of providing high-quality milk that meets the expectations of modern consumers.

In summary, homogenization is essential in the dairy industry for producing consistent, high-quality milk that meets consumer demands for texture, stability, and shelf-life.

9. Consumer Perspectives on Homogenized Milk

Consumers have varied perspectives on homogenized milk, influenced by factors such as texture, taste, convenience, and health beliefs.

1. Texture and Consistency

Many consumers appreciate the smooth and uniform texture of homogenized milk. The process of breaking down fat globules ensures that the milk does not separate, providing a consistent product that is easy to pour and use in various culinary applications. This consistency is particularly valued in households with children or in situations where milk needs to be stored for extended periods.

2. Taste

Homogenized milk tends to have a more neutral, standardized flavor, which is preferred by many for daily consumption. Its lack of cream separation means that every sip tastes the same, offering predictability that some consumers find reassuring.

3. Health and Nutrition

Some consumers view homogenized milk as healthier due to its enhanced digestibility and improved absorption of fat-soluble vitamins. The convenience of a stable, ready-to-drink product that maintains its quality over time is a significant advantage for busy lifestyles.

4. Naturalness and Tradition

On the other hand, a segment of consumers prefers non-homogenized milk, perceiving it as more natural and less processed. These individuals often value the traditional cream-on-top experience and believe that non-homogenized milk retains a richer flavor and potentially more health benefits. They might also associate non-homogenized milk with artisanal or organic farming practices, which align with their broader food preferences.

5. Environmental and Ethical Considerations

Some consumers are concerned about the environmental impact of the homogenization process, including its energy consumption. They may opt for non-homogenized milk as part of a commitment to more sustainable and ethical food choices.

In conclusion, consumer preferences for homogenized milk vary widely, with factors like texture, taste, health beliefs, and environmental concerns all playing a role in shaping individual choices.

10. Conclusion

The homogenization of milk is a vital process in the dairy industry, ensuring a consistent and appealing product for consumers. While it offers numerous benefits, including improved texture and extended shelf-life, it also raises questions about nutritional impacts and health implications. Understanding the process and its effects can help consumers make informed choices about the milk they consume.

FAQ’s

Q1. Is homogenized milk safe to drink?

Yes, homogenized milk is safe to drink. The process itself does not affect the safety of the milk, and it is often combined with pasteurization to ensure bacterial safety.

Q2. Does homogenization affect the taste of milk?

Homogenization can slightly alter the taste by creating a more uniform texture, which some people find smoother and creamier.

Q3. What is the difference between pasteurized and homogenized milk?

Pasteurization involves heating milk to kill harmful bacteria, while homogenization breaks down fat globules to prevent cream separation. Both processes are often used together but serve different purposes.

Q4. Is raw milk healthier than homogenized milk?

Raw milk may retain more natural nutrients, but it also carries a higher risk of bacterial contamination. Homogenized milk is safer to consume but may have slightly altered nutritional properties.

Q5. Can I homogenize milk at home?

While it is possible to homogenize milk at home using specific equipment, it is not practical for most consumers. Commercial homogenization is more efficient and reliable.

Q6. Why does some milk say “non-homogenized”?

Non-homogenized milk is marketed to consumers who prefer the natural cream separation and traditional taste. It is often sold in specialty and health food stores.